How Do Cleanrooms Prevent Contamination?

One frequently asked question about cleanrooms is how they work to maintain cleanliness. The goal of a cleanroom is to minimize contamination so that tasks that require extreme cleanliness can be performed. So how exactly do they prevent contamination?

What Is a Cleanroom?

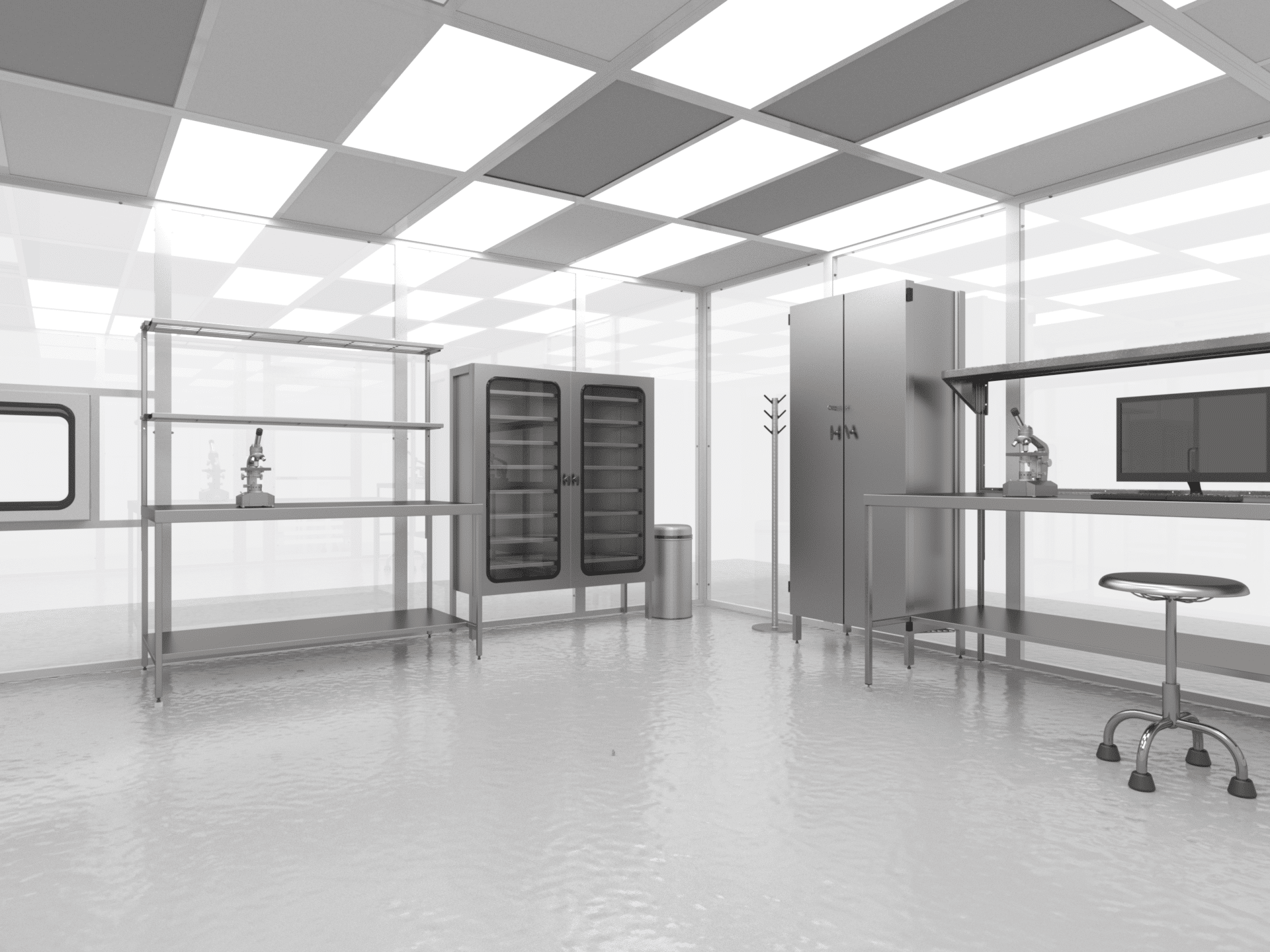

A cleanroom is a controlled environment that limits the concentration of airborne particles to specification. A wide variety of companies and organizations require that contamination be controlled so they can safely manufacture or handle valuable or delicate products or samples.

Cleanrooms work via two separate mechanisms: quarantined space and air flow with filtration. First, the space must be sectioned off and quarantined so that contamination can be controlled within this set aside area. This is done by building airtight structures, either permanent or modular, based on the needs of the organization. A cleanroom does not have to be large in order to function, but it can be the size of an entire building or manufacturing facility. Its size depends entirely on the needs of the organization. A cleanroom within a cleanroom is another possibility.

Once the cleanroom space is constructed or set up, the air within that space is cleaned continuously using a series of air locks and air flow systems. This keeps contaminants like dust or microorganisms from entering the cleanroom and removes any contaminants that are introduced.

Interior Air Flow Works to Prevent Contamination

There are two types of air flow systems that cleanrooms typically use. These are laminar air flow systems and turbulent air flow systems.

Laminar Air Flow – Laminar air flow systems blow air in parallel straight lines directed horizontally or downwards. The room is designed not to disrupt that air flow or create turbulence. In this type of system, the ceiling contains HEPA filters and the walls have outlet vents located close to the floor or within the floor. Air moves in one direction, down and out while contaminants are filtered out through the ceiling.

Turbulent Air Flow – These systems are used in situations where the room’s layout or equipment placement would create airflow dead spots if only a laminar air flow system were used. Velocity filters in the ceilings or walls mix the air in these spots and remove any particles.

Air flows through the room and into a filter which removes any contamination. The filter can be either a HEPA or ULPA filter. Both types utilize positive pressure to ensure that even in the event of leakage, air will flow from the cleanroom to the exterior environment.

The interior of the cleanroom itself is also designed to prevent contamination from settling or proliferating. The furniture within is made of hard wearing materials like stainless steel or polyurethane polymers that naturally stop bacterial growth and do not shed material. While inside, cleanroom workers wear protective clothing or items like overshoes, hairnets, gloves, and goggles to keep contamination from being tracked in or from shedding. They also do not introduce materials that might shed particulate matter such as paper or other fibrous materials.

Ultimately, a cleanroom is designed to prevent contamination from being introduced into the environment. Within the room, contamination is filtered through filters built into the ceiling or walls while the air itself circulates through and out of the room.

Technical Air Products is able to provide top-quality cleanroom solutions tailored to your specific facility and application requirements. Our commitment to delivering precision-engineered materials is a testament to our dedication to excellence. We understand the critical nature of cleanroom environments and are proud to offer modular cleanrooms that meet the highest industry standards.

If you have any questions about cleanrooms or what type of cleanroom would be best for your application, Technical Air Products can answer them. We offer softwall and rigidwall modular cleanrooms and also offer our customers custom engineered solutions to meet their specific requirements.

Leave a Reply