Category: News

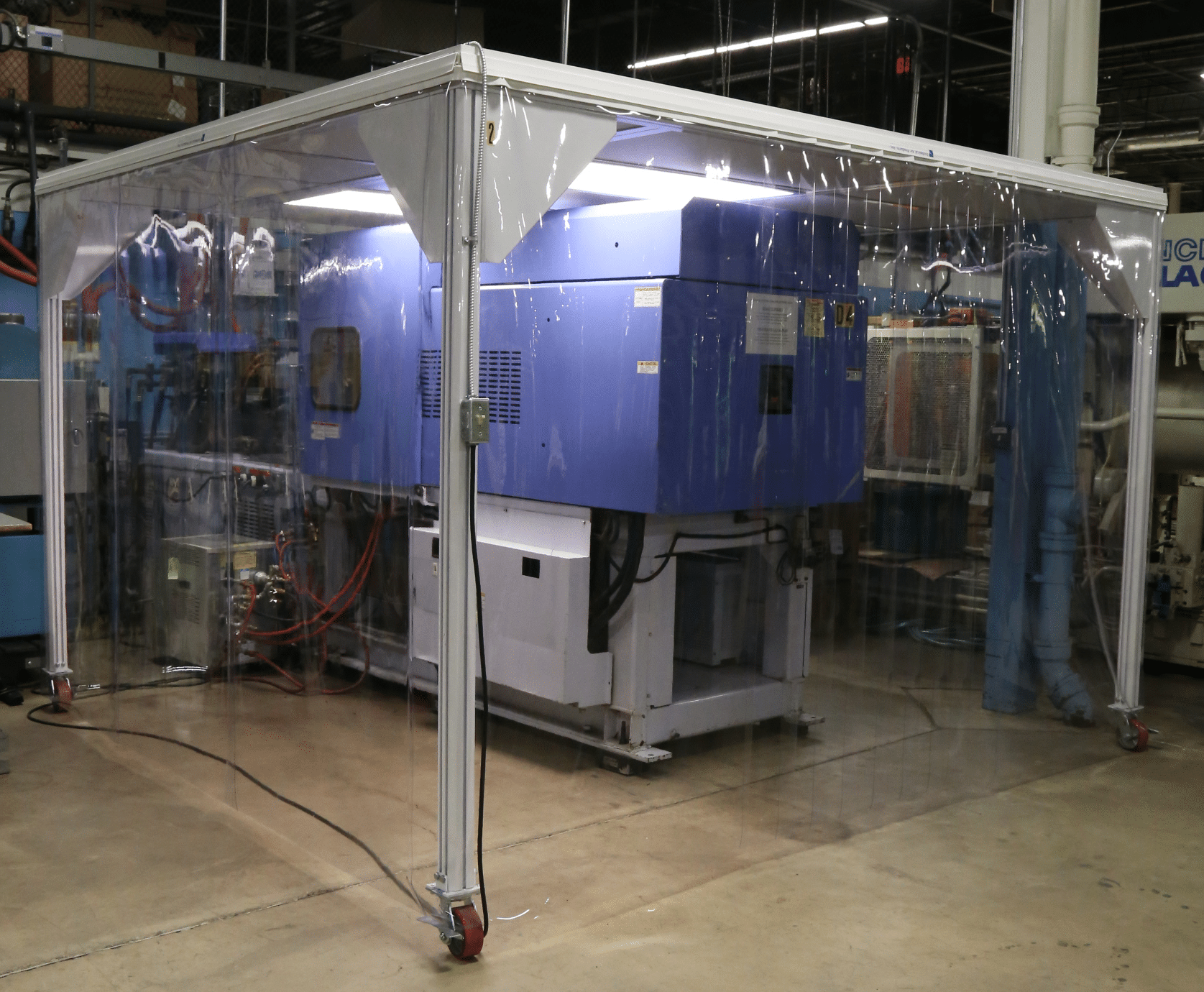

Tent cleanrooms have emerged as a flexible and innovative solution across industries because they can provide a necessary blend of versatility, efficiency, and cost-effectiveness in one product. Portable and lightweight, made from flexible materials and supported by a simple frame, they are uniquely suited for a range of applications. Understanding the ideal environments and use […]

The continuous change happening in the research and manufacturing sectors of the economy make it even more critical that businesses be as competitive as possible. Many companies in sectors like pharmaceuticals, biotechnology, and electronics have decided to invest in modular cleanrooms because they need controlled environments to ensure product quality and compliance with industry standards […]

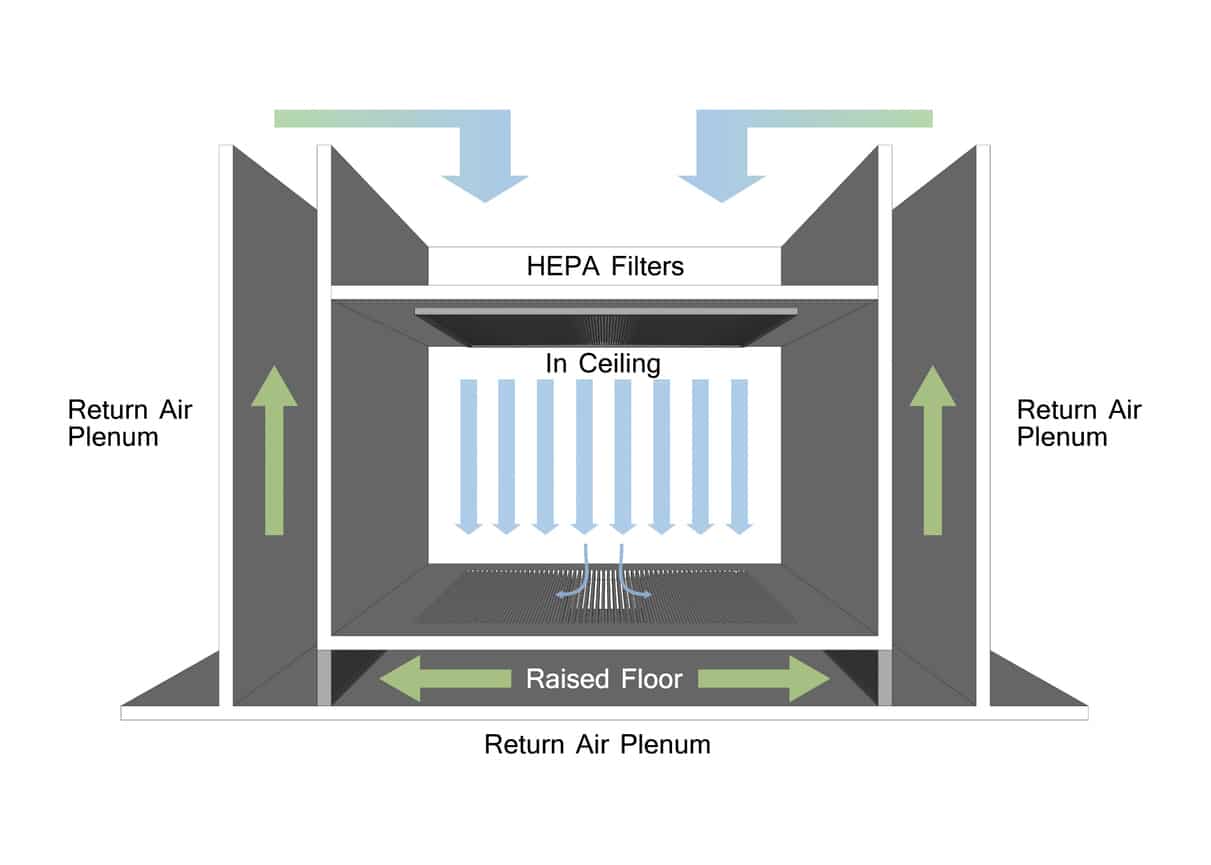

In order for a space to become an environment that is able to control contamination to specification – in other words, a cleanroom – you must quarantine that space and then filter the air within it. The cleanroom’s walls, floor, and ceiling contain the space and make it airtight, but there are additional cleanroom components […]

Technical Air Products specializes in modular cleanroom manufacturing. Our customers appreciate how affordable, flexible, and easy to install modular cleanrooms are. If you have ever wondered what is involved in modular cleanroom installation, we have answers, and we will detail them in this blog. What Is a Modular Cleanroom? A cleanroom is a controlled environment […]

Where is the best place to locate a cleanroom within your building’s space? If you are considering adding a cleanroom to your facility, this is a question you will ask yourself. The answer requires careful consideration of your building’s layout, your processes and workflow, and your specific cleanliness requirements. Let’s go over the factors you […]

If you are planning to add a new cleanroom to your facility, there are a number of decisions you should make about its design before you invest any of your resources. If you’re not certain where to start, Technical Air Products can help. In this blog we will go over four key decisions you need […]

Cleanroom maintenance is more than just a cleaning regimen. It requires implementing meticulous protocols, adhering to strict procedures, and monitoring continuously to ensure that the environment remains free from particulate and microbial contamination. It’s easy to overlook how important regular cleanroom maintenance and upkeep is to ensure productivity. It’s not just critical to manufacturing products […]

Highly controlled environments like cleanrooms require a great deal of energy to operate. They must maintain pressure, airflow, filtration, and sometimes temperature, humidity, and sound as well. All of these require electricity inputs, often continuous, in order to control contamination effectively within the space. For organizations that need to utilize cleanrooms for their operations but […]

Cleanrooms are highly controlled environments that are used for many different research and commercial purposes. Cleanroom contamination occurs most often due to the presence and behavior of the personnel in the room. Following proper safety procedures can eliminate potential contamination as well as ensure a safe environment for the staff working in the cleanroom. In […]

The design of your modular cleanroom must satisfy not only industry standards but also the specific needs of your business. Although modular cleanrooms have been used for decades in the manufacturing and scientific research sectors, they are now becoming a more affordable option for smaller companies that need controlled spaces. Customizing your modular cleanroom must […]